Thickness Planer: Difference between revisions

Jump to navigation

Jump to search

(→Usage) |

No edit summary |

||

| Line 1: | Line 1: | ||

[[Category:Tools]] | [[Category:Tools]] | ||

[[Category:Wood Shop]] | [[Category:Wood Shop]] | ||

[[File: | [[File:new_Jointer-Planer.png|upright|150px]] | ||

== Info == | == Info == | ||

*Make: | *Make: Hammer | ||

*Model: | *Model: A3-41 | ||

*Manual: | *Manual: large file--to be loaded when possible | ||

* | *As a jointer or planer (top surface) : 16" width 4 mm max cut. | ||

* As a thicknesser: 16" width, can handle between 4 mm and 225 mm board height | |||

== Usage == | == Usage == | ||

| Line 36: | Line 37: | ||

# TURN THE MACHINE "OFF", DISCONNECT IT FROM THE POWER SOURCE, and clean the table/work area before leaving the machine. | # TURN THE MACHINE "OFF", DISCONNECT IT FROM THE POWER SOURCE, and clean the table/work area before leaving the machine. | ||

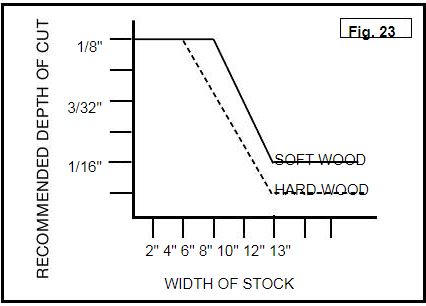

=== Recommended Depth of Cut === | === Recommended Depth of Cut (for the former machine: needs editing)=== | ||

[[File:planer_depth_of_cut.jpg|frame]] | [[File:planer_depth_of_cut.jpg|frame]] | ||

*NOTE: One revolution of the cutterhead adjusting handle will move the cutterhead up or down 1/16" | *NOTE: One revolution of the cutterhead adjusting handle will move the cutterhead up or down 1/16" | ||

| Line 45: | Line 46: | ||

*Continuous operation at more than 3/64" can cause motor damage. | *Continuous operation at more than 3/64" can cause motor damage. | ||

=== Operating Hints === | === Operating Hints (for the former machine: needs editing)=== | ||

# True Up One Face – Feed one face of the board through a jointer. Make thin cuts with each pass until the entir esurface is flat. | # True Up One Face – Feed one face of the board through a jointer. Make thin cuts with each pass until the entir esurface is flat. | ||

# Plane to Thickness – Place the surfaced side (STEP 1) face down and feed the board through a planer until the opposite side is flat. Plane both sides of the board until you achieve your desired thickness. Make thin cuts,alternating sides with each pass. If, during the planing operation, you notice the board twisting, warping or bowing,start again with STEP 1. | # Plane to Thickness – Place the surfaced side (STEP 1) face down and feed the board through a planer until the opposite side is flat. Plane both sides of the board until you achieve your desired thickness. Make thin cuts,alternating sides with each pass. If, during the planing operation, you notice the board twisting, warping or bowing,start again with STEP 1. | ||

| Line 52: | Line 53: | ||

== Maintenance == | == Maintenance == | ||

Revision as of 07:52, 5 May 2022

Info

- Make: Hammer

- Model: A3-41

- Manual: large file--to be loaded when possible

- As a jointer or planer (top surface) : 16" width 4 mm max cut.

- As a thicknesser: 16" width, can handle between 4 mm and 225 mm board height

Usage

Safety Rules

- DO NOT OPERATE THIS MACHINE until it is completely assembled and installed according to the instructions. A machine incorrectly assembled can cause serious injury.

- OBTAIN ADVICE from your supervisor, instructor,or another qualified person if you are not thoroughly familiar with the operation of this machine. Knowledge is safety.

- FOLLOW ALL WIRING CODES and recommend-ed electrical connections to prevent shock or electrocution.

- KEEP KNIVES SHARP and free from rust and pitch. Dull or rusted knives work harder and can cause kickback.

- NEVER TURN THE MACHINE "ON" before clearing the table of all objects (tools, scraps of wood, etc.). Flying debris can cause serious injury.

- NEVER TURN THE MACHINE "ON" with the work-piece contacting the cutterhead. Kickback can occur.

- SECURE THE MACHINE TO A SUPPORTING SURFACE to prevent the machine from sliding, walking or tipping over.

- PROPERLY SECURE THE KNIVES IN THE CUTTER-HEAD before turning the power "ON". Loose blades may be thrown out at high speeds causing serious injury.

- LOCK THE SPEED SETTING SECURELY before feeding the workpiece through the machine. Changing speeds while planing can cause kick-back.

- AVOID AWKWARD OPERATIONS AND HAND POSITIONS. A sudden slip could cause a hand to move into the knives.

- KEEP ARMS, HANDS, AND FINGERS away from the cutterhead, the chip exhaust opening, and the feed rollers to prevent severe cuts.

- NEVER REACH INTO THE CUTTERHEAD AREA while the machine is running. Your hands can be drawn into the knives.

- DO NOT STAND IN LINE OF THE WORKPIECE. Kickback can cause injury.

- SAVE THESE INSTRUCTIONS.and use them to instruct others. Refer to them often.

- ALLOW THE CUTTERHEAD TO REACH FULL SPEED before feeding a workpiece. Changing speeds while planing can cause kickback.

- WHEN PLANING BOWED STOCK, place the concave(cup down) side of the stock on the table and cut with the grain to prevent kickback.

- DO NOT FEED A WORKPIECE that is warped, contains knots, or is embedded with foreign objects (nails, staples, etc.). Kickback can occur.

- DO NOT FEED A SHORT, THIN, OR NARROW WORKPIECE INTO THE MACHINE. Your hands can be drawn into the knives and/or the workpiece can be thrown at high speeds.

- DO NOT FEED A WORKPIECE into the outfeed end of the machine. The workpiece will be thrown out of the opposite side at high speeds.

- REMOVE SHAVINGS ONLY with the power "OFF" to prevent serious injury.

- PROPERLY SUPPORT LONG OR WIDE WORK-PIECES. Loss of control of the workpiece can cause serious injury.

- NEVER PERFORM LAYOUT, ASSEMBLY or set-up work on the table/work area when the machine is running. Serious injury will result.

- TURN THE MACHINE "OFF", DISCONNECT IT FROM THE POWER SOURCE, and clean the table/work area before leaving the machine.

Recommended Depth of Cut (for the former machine: needs editing)

- NOTE: One revolution of the cutterhead adjusting handle will move the cutterhead up or down 1/16"

- You can make an 1/8" depth of cut in soft woods up to 6" wide and in hard woods up to 4" wide. (See Fig. 23)

- For 10", 12", and 13" wide soft wood, use a maximum depth-of-cut of 1/16"

- For 10", 12", and 13" wide hard wood, use a maximum depth-of-cut of 3/64"

- IMPORTANT: A shallow depth-of-cut will produce a better finish.

- Continuous operation at more than 3/64" can cause motor damage.

Operating Hints (for the former machine: needs editing)

- True Up One Face – Feed one face of the board through a jointer. Make thin cuts with each pass until the entir esurface is flat.

- Plane to Thickness – Place the surfaced side (STEP 1) face down and feed the board through a planer until the opposite side is flat. Plane both sides of the board until you achieve your desired thickness. Make thin cuts,alternating sides with each pass. If, during the planing operation, you notice the board twisting, warping or bowing,start again with STEP 1.

- Support both ends of the long workpieces.

- For best results, engage the cutterhead lock before planing. Plane with the grain only. Keep the planer table clean.Occasionally, wax the table surface to reduce friction during the planing operation.5. Cross-cut your lumber to the final length.The knives on the planer will not wear evenly if the wood is fed through the same spot on the tableevery time. Feed the wood through the planer at different spots on the table when possible to help eliminate uneven wear of the knives